You Are Here:Home > News Center

> Industry Dynamics

News navigation

Recommended news

Why is PCR regenerated material used in the manufacturing of insulation boards

source:chuhan8.com | Release time:2025-02-10

The main reasons for using PCR regenerated materials in the manufacturing of insulation boards are as follows:

1. The significance of environmental protection is significant

Reduce plastic waste: PCR recycled materials come from post consumer plastic waste, such as plastic bottles, plastic films, etc. Using it for insulation board manufacturing can effectively reduce the amount of landfill and incineration, reduce the pollution of plastic waste to soil, water sources, and air, and protect the ecological environment.

Reduce resource consumption: Traditional plastic production relies on non renewable resources such as oil. Using PCR recycled materials can reduce the exploitation of primary resources, achieve resource recycling, and promote the sustainable development of the industry.

Assisting in carbon reduction: Compared to producing virgin plastics, the production process of PCR recycled materials consumes less energy and emits fewer greenhouse gases such as carbon dioxide, which helps alleviate global climate change and meets the development requirements of "carbon neutrality" and "carbon peak".

2. Significant economic benefits

Reducing raw material costs: By using waste plastics as raw materials, the procurement cost of PCR recycled materials is usually lower than that of virgin plastics, which can reduce the production cost of insulation boards and improve the economic efficiency and market competitiveness of enterprises.

Stable raw material supply: In the context of increasingly scarce resources, the application of PCR regenerated materials helps to ensure the stability of raw material supply, reduce dependence on external resources, and mitigate risks caused by fluctuations in raw material prices or supply shortages.

3. Suitable performance characteristics

The insulation performance can meet the requirements: After appropriate treatment and formula optimization, the insulation board made of PCR recycled materials can have good insulation performance, meeting the insulation needs of buildings and other structures. If used for building exterior wall insulation, it can effectively reduce heat transfer and energy consumption.

Good processing performance: PCR regenerated materials have certain plasticity and processing performance, which can adapt to the production process of insulation boards, such as making insulation boards of various specifications and shapes through extrusion, molding, etc., to meet the needs of different projects.

Can improve certain properties: Some PCR recycled materials can also improve other properties of insulation boards, such as some plastic PCR recycled materials that can enhance the crack resistance, toughness, and overall quality and service life of insulation boards.

4. Policy oriented promotion: Governments around the world have introduced encouraging policies and regulations to promote the application of recycled materials in order to achieve sustainable development goals. The use of PCR regenerated materials meets policy requirements, which helps companies obtain policy support and benefits, enhance their social image and market recognition.

1. The significance of environmental protection is significant

Reduce plastic waste: PCR recycled materials come from post consumer plastic waste, such as plastic bottles, plastic films, etc. Using it for insulation board manufacturing can effectively reduce the amount of landfill and incineration, reduce the pollution of plastic waste to soil, water sources, and air, and protect the ecological environment.

Reduce resource consumption: Traditional plastic production relies on non renewable resources such as oil. Using PCR recycled materials can reduce the exploitation of primary resources, achieve resource recycling, and promote the sustainable development of the industry.

Assisting in carbon reduction: Compared to producing virgin plastics, the production process of PCR recycled materials consumes less energy and emits fewer greenhouse gases such as carbon dioxide, which helps alleviate global climate change and meets the development requirements of "carbon neutrality" and "carbon peak".

2. Significant economic benefits

Reducing raw material costs: By using waste plastics as raw materials, the procurement cost of PCR recycled materials is usually lower than that of virgin plastics, which can reduce the production cost of insulation boards and improve the economic efficiency and market competitiveness of enterprises.

Stable raw material supply: In the context of increasingly scarce resources, the application of PCR regenerated materials helps to ensure the stability of raw material supply, reduce dependence on external resources, and mitigate risks caused by fluctuations in raw material prices or supply shortages.

3. Suitable performance characteristics

The insulation performance can meet the requirements: After appropriate treatment and formula optimization, the insulation board made of PCR recycled materials can have good insulation performance, meeting the insulation needs of buildings and other structures. If used for building exterior wall insulation, it can effectively reduce heat transfer and energy consumption.

Good processing performance: PCR regenerated materials have certain plasticity and processing performance, which can adapt to the production process of insulation boards, such as making insulation boards of various specifications and shapes through extrusion, molding, etc., to meet the needs of different projects.

Can improve certain properties: Some PCR recycled materials can also improve other properties of insulation boards, such as some plastic PCR recycled materials that can enhance the crack resistance, toughness, and overall quality and service life of insulation boards.

4. Policy oriented promotion: Governments around the world have introduced encouraging policies and regulations to promote the application of recycled materials in order to achieve sustainable development goals. The use of PCR regenerated materials meets policy requirements, which helps companies obtain policy support and benefits, enhance their social image and market recognition.

Previous:

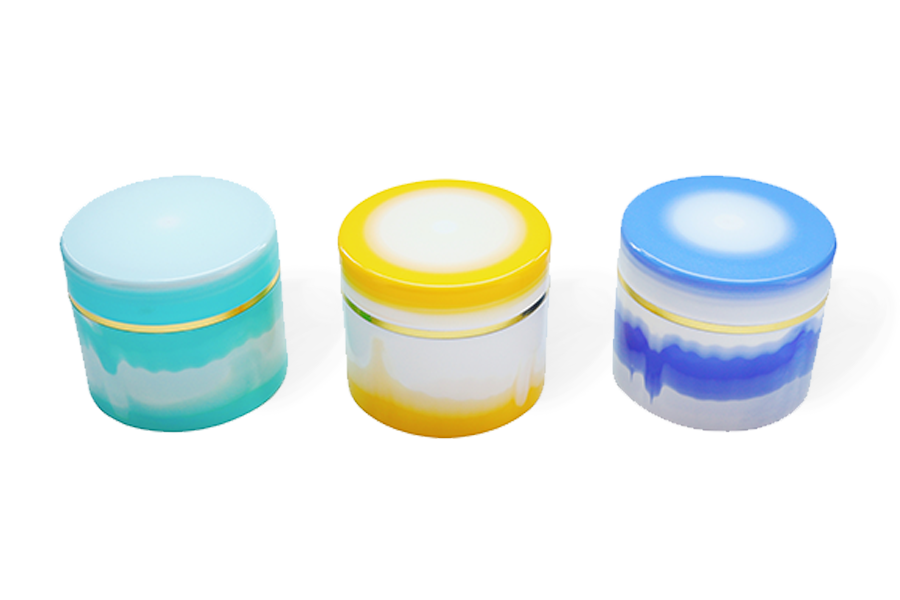

Why do face cream cans use PET plastic bottles

Next:

Application of PET plastic bottles in beverage pa…

【Related articles】

【Related Products】

- CHANGSHU SHINE PLASTIC INDUSTRY CO.,LTD Phone:0512-52557888 Mailbox:shenshisuye@163.com Company address:No. 20 Guangyuan Road, South Development Zone, Zhitang Town, Changshu City, Jiangsu Province

-

Scan your phone

Scan your phone

wechat number:

wechat number:

home

home

WeChat

WeChat

telephone

telephone